How to Choose the Right Laser Fume Extraction Unit for Your Business Needs

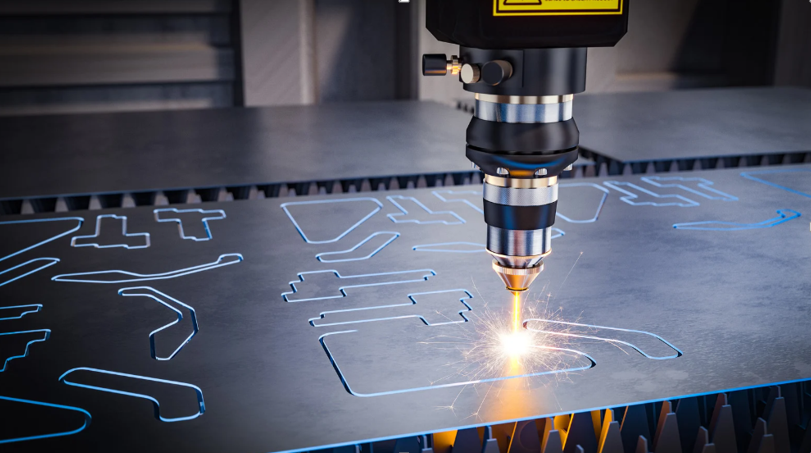

Laser cutting, engraving, and marking are essential in many industries, but they also produce hazardous fumes and particulates that can compromise both worker safety and product quality. Without proper extraction, airborne contaminants can damage equipment, reduce precision, and lead to health risks over time. Investing in reliable laser fume extractors ensures cleaner air, compliance with safety standards, and greater efficiency. Selecting the right unit, however, requires careful consideration of your industry’s specific demands and long-term operational goals.

Assessing Your Application Requirements

The first step in selecting a fume extraction unit is to determine the type of laser process your business utilizes. Different processes generate varying levels of fumes and particulates. For example, laser marking produces fine particles and odors, while laser cutting often generates heavier smoke and more substantial debris. Identifying the material you are working with, metals, plastics, or composites, is crucial, as each produces distinct byproducts that require tailored filtration solutions. Determining whether you require fume extraction for your laser marking system is a vital step in planning the optimal solution.

Filtration Efficiency and Airflow Capacity

An effective laser fume extraction unit must combine strong airflow with advanced filtration. High-efficiency filters, such as HEPA and activated carbon, capture both microscopic particulates and harmful gases. The airflow capacity should be matched to the volume of fumes produced by your operation. Units with adjustable airflow settings offer flexibility for businesses that handle multiple applications. By ensuring the unit can sustain consistent performance, companies protect both their workforce and their precision machinery.

Workplace Safety and Compliance

Beyond improving air quality, proper fume extraction is crucial for complying with health and safety regulations. Prolonged exposure to toxic fumes can cause respiratory issues and long-term health complications. Investing in a unit that aligns with occupational safety standards demonstrates a commitment to employee well-being and compliance with workplace regulations. This not only protects workers but also strengthens overall operational integrity.

Maintenance and Operational Costs

The cost of ownership is an important factor in selecting the right unit. While upfront investment is necessary, long-term value comes from units designed for durability, energy efficiency, and easy filter replacement. Choosing an extraction system that offers accessible maintenance features helps minimize downtime and lowers overall costs. Businesses should also consider whether they require portable systems for flexible workspaces or fixed units for continuous, high-volume operations.

Industry Applications and Air Quality

The benefits of fume extraction extend across various sectors, including electronics, medical device manufacturing, and aerospace, where precision and cleanliness are crucial. The way laser fume extractors enhance air quality in high-precision industries demonstrates their value in preventing contamination, safeguarding sensitive products, and maintaining a controlled environment. Cleaner air also improves employee productivity by reducing exposure-related fatigue and health issues, ultimately supporting business growth.

See also: 5 Benefits of Biotech Skids for Manufacturing

Long-Term Value of the Right Choice

The right laser fume extraction unit is not just an accessory but an integral part of your production process. It protects workers, extends the lifespan of equipment, and ensures consistent output quality. By carefully matching your system to your materials, methods, and operational scale, you create a safer, more efficient workplace. A well-chosen extraction unit supports long-term sustainability, positioning your business to meet future demands with confidence.

Conclusion

Selecting the right laser fume extraction unit requires striking a balance between immediate operational needs and long-term business goals. By focusing on application requirements, filtration performance, compliance, and overall cost efficiency, businesses can ensure cleaner air, safer workplaces, and higher-quality results. Investing in the right system enhances productivity while protecting both employees and equipment.